Oil cup standard diameter: 90 mm Φ

Oil cup plate size: 240 * 100 mm

The print head pressure: 120 par

Fastest speed: 1200 cycles per hour

The thickness of the standard calendar: 300 mm

Voltage/power: 220/55 hz / 50 w

Air pressure requirements: 4 to 6 bar

Machine weight: 112 kg

The fuselage size: 750 * 570 * 1360 (LxWxHmm)

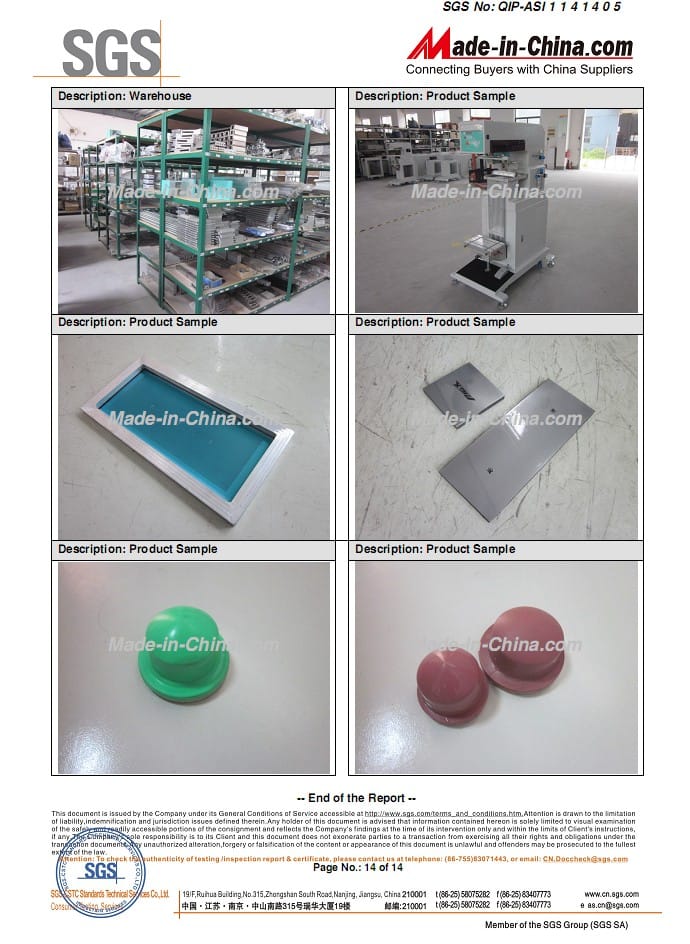

The samples display:

The workbench design around before and after the position adjustment can be realized.Use of the world's top pneumatic components, stable performance.High quality solid metal casting body, the structure is strong.To offer them with seal oil scraper system, reduce pollution.Do not produce ink splashes and peculiar smell.Oil cup use precision ceramic ring blade structure, unique.Welcome to inquire our factory production of single color pad printing machine price.Our other pad printing machines: desktop moving printing machine, shuttle pad printing machines, conveyor belt moving printing machine, monochrome printing machine, two-color shuttle moving printing machine, two-color conveyor belt moving printing machine, four-color shuttle moving printing machine, four-color conveyor belt moving printing machine, six color shuttle moving printing machine, six color pad printing machine conveyor belt, the eight color pad printing machine conveyor belt, the eight color pad printing machine conveyor belt.Our other products: silk screen pad printing inks, printing plate, pad printing steel piece, pad printing blade, rubber pad printing head, many cup, move the user printing consumables such as basin;Fuel injection equipment, the membrane equipment, washing equipment, drying equipment, such as water transfer printing equipment.

Pad printing machine applicable industry:

Plastic industry, toy industry, glass industry, metal industry, electronics, sporting goods, stationery industry, optical studies, IC packaging industry, etc.Pad printing machine suitable for: ruler, pen, ball bearings, doll eyes, watches, cameras, hair dryer shell, ceramics, medical appliance, the racket, tapes, electronic components, IC, CPU, DRAM, computer case, buttons, decorative signs, such as mobile phone casing of printing.The principle of moving printing machine is the design of the required printing first by using the method of photographic plate making, make steel version into gravure via special silicone seal head again transfer printing on the printed material, and can be in accordance with the material of products is different, modulation of special ink, so that the quality guaranteed.Pad printing machine process is divided into the following four points: the pad printing machine applicable industries: plastic industry, toy industry, glass industry, metal industry, electronics, sporting goods, stationery industry, optical studies, IC packaging industry, etc.Pad printing machine suitable for: ruler, pen, ball bearings, doll eyes, watches, cameras, hair dryer shell, ceramics, medical appliance, the racket, tapes, electronic components, IC, CPU, DRAM, computer case, buttons, decorative signs, such as mobile phone casing of printing.