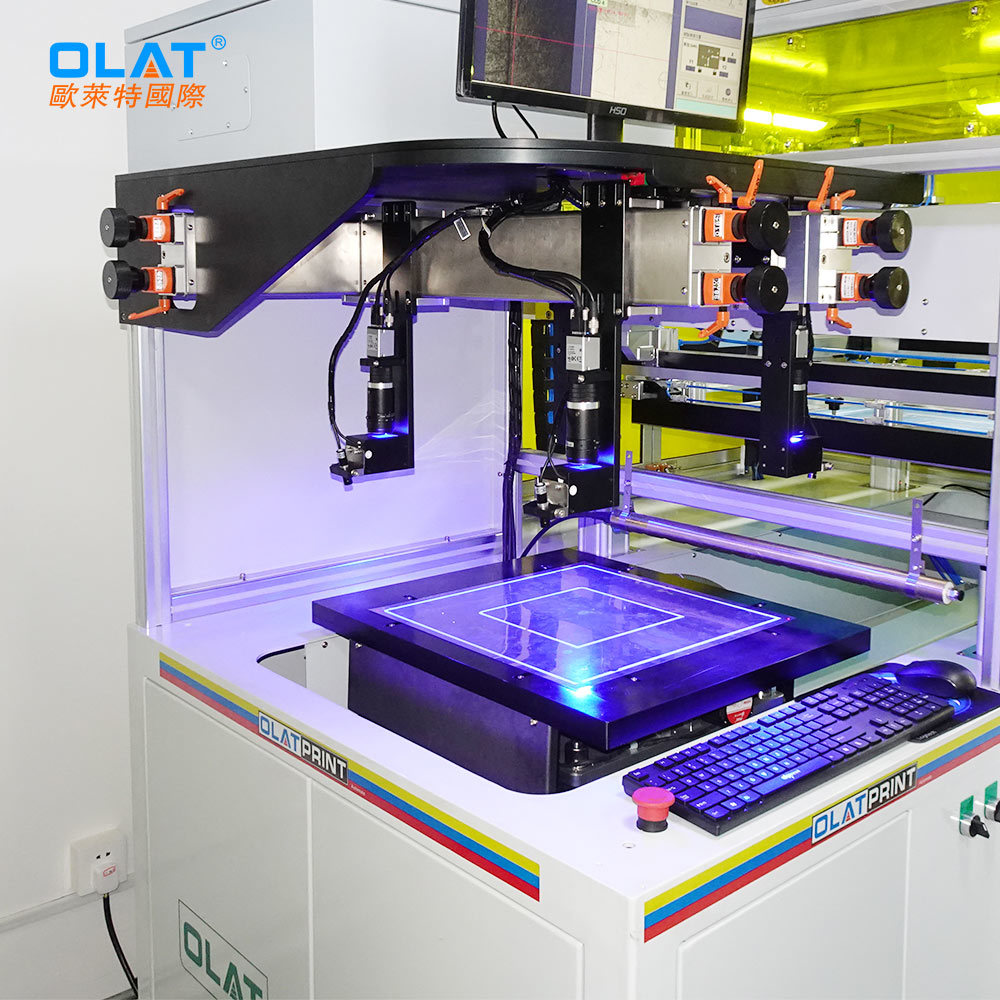

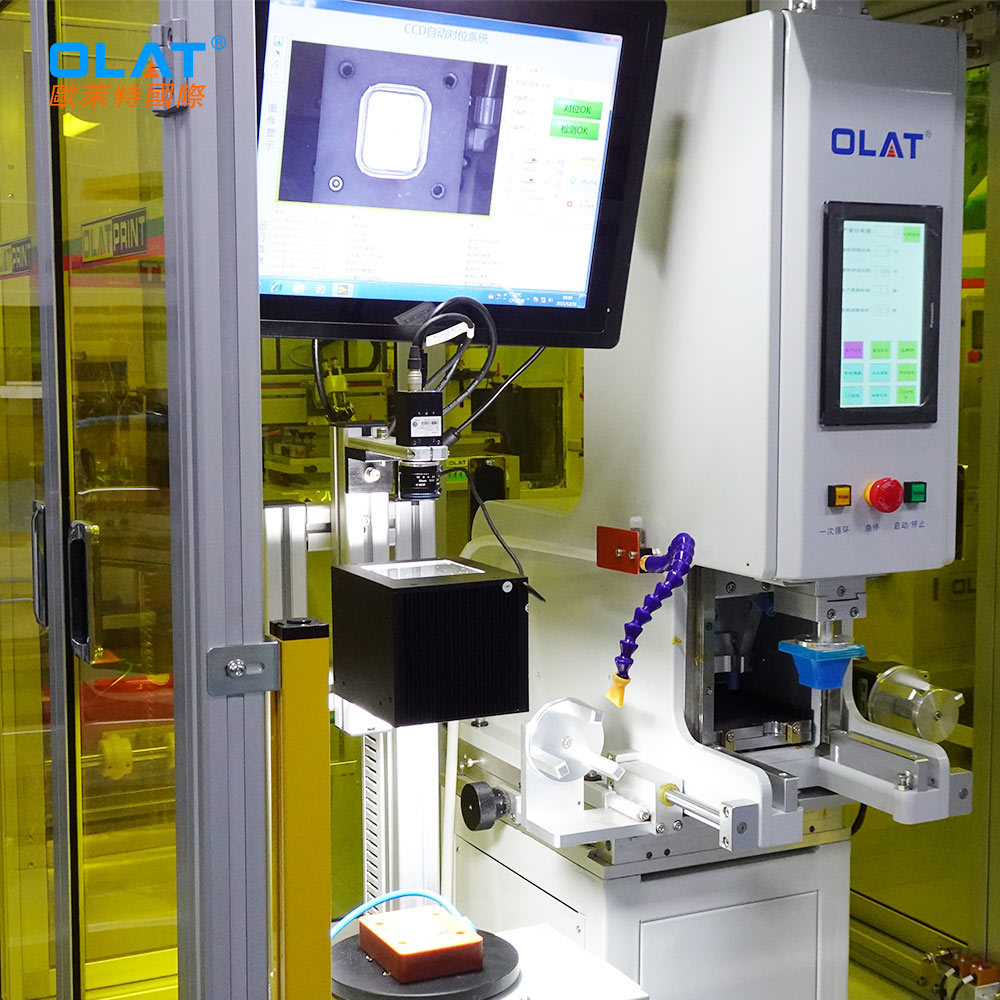

Printing technology is changing with each passing day. Nowadays, printing technology can be applied to almost all kinds of material surfaces. Pad printing technology can print patterns on irregular curved surfaces. Surface materials include all kinds of materials, such as plastic, metal, glass, ceramics, leather, bakelite and other materials. Products, in addition to this, are also very suitable for small surface or small size products. With the advent of the era of industrial automation, machine automation has been successfully combined with pad printing technology, replacing the previous steps of manual placement of substrates, reducing errors and losses caused by human fatigue. Machine vision systems play an integral role in the process of pad printing automation.

Features of automatic visual pad printing system:

1. Stable and efficient production, the printing efficiency is maintained at 5 seconds per piece.

2. High degree of automation, one person can operate multiple software at the same time.

3. The visual alignment interface of the upper computer is closely connected with the touch screen operation interface, and the production status can be observed in real time.

4. The software intelligently saves the material model formula and realizes one-key operation of changing materials.