This process, which looks like "seal and stamping", is called "pad printing". In life, the printing on many things is inseparable from pad printing, the most common is the printing of mug patterns.

The pad printing process is really comfortable, a large soft silicone head, after sticking with ink, "slaps" the object that needs to be printed. The soft silicone head fits the surface of the object tightly. In their intimate contact, the ink is transferred, and the printing realizes the great harmony of the universe;So, what are the principles and characteristics of pad printing? What are the main applications? What are the precautions? Below, I will tell you in detail.

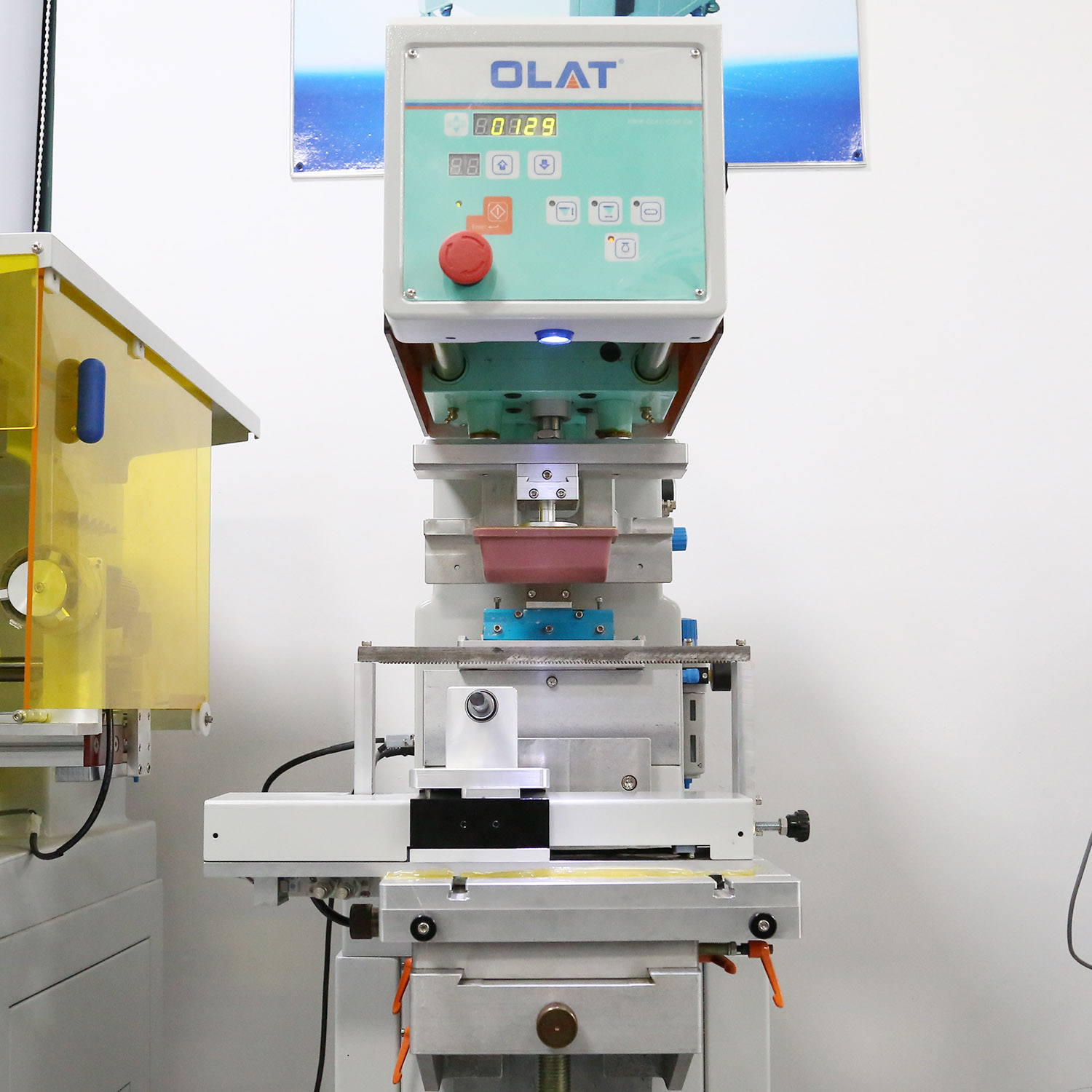

The principle of pad printingThe English name of "pad printing" is "Pad Printing". Pad refers to the printing plate, which is usually etched to form embedded grooves, similar to the feeling of intaglio.The printing process involves spraying ink on the etched plate and scraping off excess ink with a retractable scraper. At this point, the solvent in the ink left in the grooves of the etched plate evaporates, forming a "jelly". When the silicone head descends and hits the etched plate, it can easily stick the inkThe shape of the silicone head is also very particular: it must be able to produce a rolling action to exhaust the excess air on the etched plate and the ink surface.As an important tool for pad printing, the silicone holder has different models and degrees of softness. The specific type of silicone head to be used depends on the size, shape and rolling strength of the printing pattern.The selection principle is: the harder the silicone head, the better the ink transfer effect. After printing about 50,000 times, if the silicone head shows obvious signs of wear, it should be replaced in time, and care must be taken not to damage the surface of the silicone head.